Heavy Metal Precipitants

Heavy metals are commonly found in both process waters, rinse waters and general wastewaters from various industries including:

- Electroplating

- Electronics industry

- Metal processing industry

- Chemical industry

- Photographic industry

- Iron and steel manufacturing and processing

- Printing factories

- Refineries

- Power Stations

- Waste disposal treatment sites

- Leachate treatment

- Incinerators

- Leather products factories

Heavy metals are extremely toxic to the environment at very low levels and tend to accumulate in living organisms. Due to this the legislators are introducing tighter controls and limits for these materials.

Heavy metals are removed by various techniques including chemical precipitation, ion exchange, adsorption, electrolysis and various forms of filtration.

Chemical precipitation by the hydroxide and carbonate, precipitation is justified by their low costs, they can be performed by a simple pH adjustment (eg. Caustic, lime or soda ash). There are several issues that may occur:

- Precipitation of the required heavy metal doesn’t occur in the presence of complexing agents e.g. EDTA or amines or in the presence of cleaners.

- The precipitates are in the form of light tiny flocs requiring an extra coagulation/flocculation.

- Large volumes of sludge are generated, inducing additional waste-disposal costs.

- Regulation requirements are not always met using hydroxide and carbonate precipitation alone.· Each dissolved metal has its own distinct pH level for maximum hydroxide precipitation. Because metal hydroxides are increasingly soluble above or below their individual maximum precipitation point, even a slight pH adjustment to precipitate one metal may put another back into solution.

Sulphide precipitation is an alternative which precipitates metals to lower solubility levels however these materials have to be used in alkaline conditions to prevent release of toxic gas and there is the potential to overdose these products leading to an accidental release.

The alternative is to use a sulphur based organic polymer often based on Dithiocarbamate. Aqua Advice have over 30 years experience using these products and have developed proven methods. Products vary in the metals that they will remove and the toxicity of the product.

Please contact us for further information including the range of metals that can be removed.

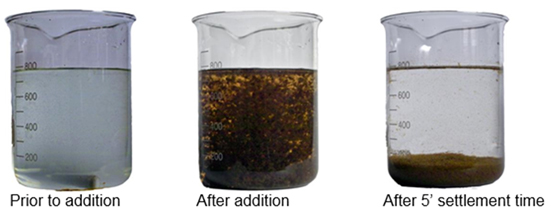

Treatment of a Nickel containing pH adjusted wastewater with L-1R

We have the wastewater chemical treatment solutions to optimise your water treatment plant and equipment.

A comprehensive range of effluent treatment plant from upgrades of your existing facilities to complete turnkey projects.

With over 30 years experience in the treatment of industrial wastewater, your effluent treatment plant will be in safe hands.

Aqua Advice

Trusted for innovative Solutions in the treatment of industrial wastewater.

“The system solved the problem of sulphates in our effluent. This has allowed us to discharge to sewer meeting our consent to discharge and saving the cost of external tankers.” - Rimex Metals

Contact Aqua Advice: